steel pipe wall thickness testing|metal pipe wall thickness : makers Ultrasonic thickness measurement (UTM) is a non-destructive testing method used to inspect the metal thickness of ship hulls, piping and structural steel. Thickness measuring is essential . TD Comfort Growth. 23.360. +0.050. +0.21%. Find our live Td Comfort Growth Portfolio - I fund basic information. View & analyze the TDB888 fund chart by total assets, risk rating, .

{plog:ftitle_list}

WEB25 de set. de 2023 · Assine. Resultado da Quina de hoje (25/09/23): Concurso 6250. 45 - 77 - 53 - 01 - 78. A Caixa realiza o sorteio ao vivo direto pelo YouTube: Resultado da .

May 29, 2020 For manual thickness measurements, the 39DL PLUS™ gauge and 45MG gauge with Single Element software provide instant digital readings of typical metal pipes and tubes to a .Abstract. Frequent NDT inspection in pipes seeks to assess if the pipe wall thickness has been altered (eroded/corroded) over time. Even the slightest change can affect the pipes’ ability to .Ultrasonic testing, or UT as it is commonly called, is the procedure of introducing an ultra high-frequency sound wave into the exterior side of a pipe or some other type of material, and reflecting the sound wave echo from its interior surface to .

Ultrasonic thickness measurement (UTM) is a non-destructive testing method used to inspect the metal thickness of ship hulls, piping and structural steel. Thickness measuring is essential .Ultrasonic testing, also known as ultrasonic NDT (non-destructive testing) or simply UT, is a very powerful non-destructive test method using sound waves to detect cracks and defects in parts and materials. It can also be used to .

ATS NDT performs offers ultrasonic thickness testing (UTT) to determine material thickness and to measure the thickness of coatings and/or linings. . many industrial plants and facilities have called on ATS to measure boiler tube . Pipe wall thickness calculation is one of the important basic activities for every piping engineer. Process plants deal with the fluids that flow inside the pipe at high pressure and temperature.So, the pipe deals with high circumferential pressure which can cause the bursting of the pipe if the pipe schedule or thickness is not enough. Hence, The designers need to find .

Pipe wall thickness calculation using Barlow´s formula. On the other hand, as opposed to the thin wall assumption or membrane theory, there is the curved plate or thick wall pipe formulas derived from Lame´s theory whose use is .Bond Testing; Thickness Gauges . The single most important application for ultrasonic gauging is measuring the remaining wall thickness of metal pipes, tanks, structural parts, and pressure vessels that are subject to internal corrosion that can't be seen from the outside. Corrosion gauges are designed for this type of measurement, using .Wall Thickness Measurement . Lior PICK 1, Ron PINCU 1, Rachel LIEBERMAN 1 . 1 Vidisco Ltd.; Or-Yehuda, Israel . Phone: +972 3 5333001, Fax: +972 3 5333002; e-mail: [email protected] . Abstract . Frequent NDT inspection in pipes seeks to if the pipe wall thickness has been altered (eroded/corroded) assess

Criteria for Minimum Pipeline Wall Thickness Calculation. The wall thickness for the CS Line pipe shall be calculated based on permissible hoop stress due to internal pressure. In accordance with ASME B31.4, clause 403.2.1, The nominal wall thickness of straight sections of steel pipe shall be equal to or greater than t n determined by the . External Non Destructive Testing / Pipe work condition assessment API offers the latest technology to scan external pipe work assets; from this we can measure internal/external pit depths, wall thicknesses, ageing and corrosion levels. Utilising a specialist assessment system, an ultrasonic delivery driver is attached to the pipeline, the site technician measures .An 8-in.-diameter pipe with a wall thickness of 0.3 in. was used to confirm the system`s ability to measure total wall thickness. Calibration data were acquired at thicknesses of 0.3, 0.4, and 0.6 in. At least three values are needed to convert the standard logarithmic-output response to a linear response for subsequent values.

Ultrasonic Thickness Testing (UTT) is a method for determining the extent of corrosion and erosion on the walls of piping, vessel, storage tank, and other assets. MISTRAS offers UTT spot inspections, and long-term, remote wall thickness monitoring for pipes and vessels in high-temperature and hard-to-access locations.Example - Allowable Pressure in a Steel Pipe. The allowable pressure in a 4 inch schedule 40 carbon steel pipe with outside diameter 4.5 in, wall thickness 0.237 in, thickness tolerance 12.5% and allowable stress 16000 psi - can with quality factor E for steel 0.8 and wall thickness coefficient 0.4 be calculated as

Waygate Technologies’ ultrasonic thickness gauges are non-destructive testing (NDT) measurement tools used to inspect metal thickness and structural steel - which is essential across many industries, from Automotive and Aerospace to Oil & Gas and Manufacturing.Thickness testing is done in order to monitor for possible damage/defects .

The Pipe Integrity Testing method gives an average value of minimum wall thickness over the length of the pipe. Therefore, the method can recognize minor levels of uniform corrosion and major levels of isolated pitting corrosion, but a pipe with high levels of isolated degradation will appear to have minor loss overall.In the field of industrial ultrasonic testing, ultrasonic thickness measurement (UTM) is a method of performing non-destructive measurement (gauging) of the local thickness of a solid element (typically made of metal, if using ultrasound testing for industrial purposes) based on the time taken by the ultrasound wave to return to the surface. This type of measurement is .Or reveal in parent metal, HAZ or fusion line longer than 3.2mm or deeper than 12.5% of wall thickness. CVN impact test: (Required PSL2 pipe, for seamless shall be tested with pipe body, for welded tests including pipe body . 3756 meters carbon steel pipe API 5L X52 PSL2 (ISO 3183 L-360N) OD 20” with type of LONGITUDINAL SUBMERGED ARC .

thickness of pipe wall

Compared to steel pipe installed in the 1950’s, and where a 1 mil per year (MPY) corrosion rate could be reliably assumed, most open water cooling or process water systems average 3- 5 MPY or greater today. . With the original pipe .

Ultrasonic Thickness Measurement (UTM) is one of the techniques used to determine the condition and wall thickness of tanks, vessels, boilers, pipelines etc..Wall Thickness up to 5.500″ Thick; Scope. ASTM A106 and ASME SA106 covers seamless carbon steel nominal wall pipe for high-temperature service. Suitable for bending, flanging and similar forming operations. . Inspection test pressures produce a stress in the pipe wall equal to 60% of specified minimum yield strength (SMYS) at room .Corrosion allowance for wrought steel pipe (CS, LAS & LTCS) is mostly taken 3 mm and zero mm for stainless steel pipes. . I hope You have got the overview of the pipe wall thickness calculation, You can practice for other cases following the mentioned steps for better understanding. . EN 10204 3.1 VS EN 1024 3.2 TEST CERTIFICATES April 10 .

Element provides precise ultrasonic testing (UT) services, detecting tiny defects in various industries, ensuring compliance, and enhancing safety standards. . Pipe wall thickness ; Phased array ultrasonic testing . . American Metal Society. AMS-STD-2132, AMS-STD 2154, AMS 2630, AMS 2631, AMS 2632, AMS 2634 .

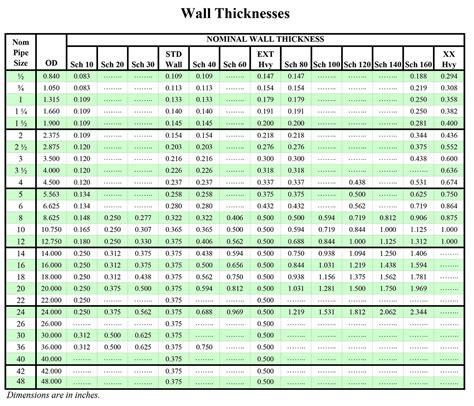

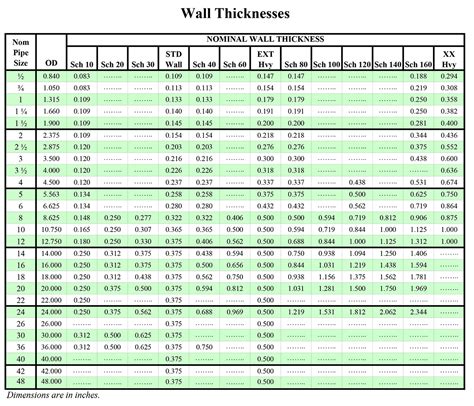

⬇️ Download Pipe Schedule Chart ASME B36.19. PIPES WALL THICKNESS IN MILLIMETERS (BY DN/SCHEDULE) CARBON AND ALLOY STEEL PIPES (ASME B36.10M) The table shows the wall thickness in millimeters for combinations of pipe DN (nominal diameter) and SCH (pipe schedule) – for carbon/alloy steel ASTM grades (according to the ASME B36.10M .Learn various pipe inspection, testing & marking requirements such as visual, dimensional inspection. . Tolerances for Pipe Wall Thickness. Nominal Pipe Size Carbon Steel Stainless Steel ; NPS : DN : ASTM A53M & 106M : . Minimum Wall Pipe ; Requirements for Carbon Steel Pipe for Hydrofluoric Acid Alkylation Service :Pipe sizes, inside and outside diameters, wall thickness, schedules, moment of inertia, transverse area, weight of pipe filled with water - U.S. Customary Units. ASME/ANSI B36.10/19 - Carbon, Alloy and Stainless Steel Pipes - Dimensions - Metric UnitsStandard Pipe Schedules and Sizes Chart Data for ANSI / ASME B36.10M and API 5L. Data given in based on the NPS Tables given by ANSI B36.10M and includes Pipe wall thickness, outside diameter, nominal diameter.

Mode 1 contact measurements are commonly recommended when minimum material thickness does not fall below approximately 0.25 mm (0.010 inches) of plastic or 0.5 mm (0.020 inches) of metal, precision required is not better than +/-25 micrometers (0.001 inch), test material is at or close to room temperature, and geometry permits contact coupling.SELECTION TALE FOR DUCTILE IRON PIPE NSF ® Certified to ANS I/ NS 61 866.DIP.PIPE U.S. PIPE AND FOUNDRY COMPANY 866.DIP.PIPE WWW.USPIPE.COM P 3 U.S. PIPE USP 0550 PRESSURE CLASSTHICKNESS CLASS RISD 01.1 Size Inches Pressure Class psi Nominal Thickness Inches OD* Inches TYTON® Joint TR FLEX® Joint HP LOK® Joint 4 350 .

Steel Pipe for Water Transmission . 1. Calculations for verification of pipe design and fittings reinforcement and/or test data. 2. . 3. Defective linings as identified in AWWA C205 shall be removed from the pipe wall and shall be replaced to the full thickness required. .

A reversible anvil lets you adapt the gauge to the shape of the object you are measuring. Use the round face on the anvil to measure the wall thickness of pipe, tubing, and other curved surfaces. Use the flat face to measure sheet metal, paper, and other flat stock.

ndt pipe thickness

Data desta versão: 21 de agosto de 2014. O REGULAMENT.

steel pipe wall thickness testing|metal pipe wall thickness